-

Address: 31/62A Mallan vilai Mulagamoodu,

Thuckalay, Tamil Nadu 629167 -

Call Us:

99435 18080

Address: 31/62A Mallan vilai Mulagamoodu,

Thuckalay, Tamil Nadu 629167

Call Us:

99435 18080

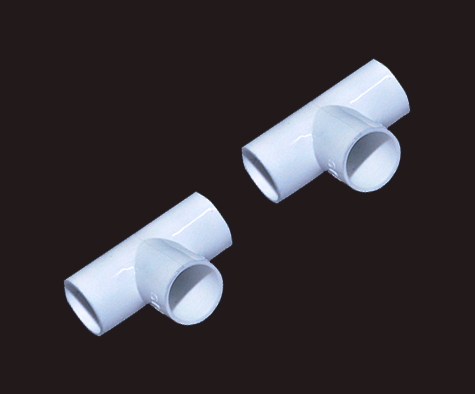

Electrical PVC conduit tee couplers are components used in electrical installations to connect and secure PVC conduits at junctions. PVC (polyvinyl chloride) conduit is a durable, non-metallic tubing system commonly used for electrical wiring protection in residential, commercial, and industrial settings.

A tee coupler is a fitting that allows the branching of conduits in a T-shaped configuration. It has three openings: two on one side and one on the other side, forming the shape of the letter "T." The tee coupler is designed to be compatible with PVC conduits of the same size.

The tee coupler is used to join three conduits together at a junction point, allowing electrical wires to pass through each conduit. It provides a secure and watertight connection between the conduits, ensuring the protection and organization of the wiring system. The coupler is typically made of PVC material, which is resistant to corrosion, impact, and various environmental conditions.

An L coupler is designed in the shape of the letter "L" and has two openings on either end. One opening allows the insertion of a straight PVC conduit, while the other opening enables the continuation of the conduit in a different direction, forming a right angle.

The purpose of an L coupler is to provide a secure and watertight connection between two PVC conduits at a 90-degree angle. It ensures that electrical wires can pass through the conduit system smoothly while maintaining the integrity of the wiring installation.

During installation, the L coupler is inserted into the open ends of the conduits, and the fittings are connected using solvent cement or glue specifically formulated for PVC. This creates a strong and permanent bond between the conduits and the coupler, ensuring a reliable connection.

A long bend is designed with a large radius, typically 36 inches or more, which allows for a gentle and gradual change in the direction of the conduit. This is in contrast to standard bends or elbows, which have a smaller radius and create sharper turns.

The purpose of a long bend is to minimize the stress and strain on electrical wires when routing them through a conduit system. The gradual bend helps prevent wire damage or kinking, especially when dealing with larger wire sizes or when the conduit needs to navigate around obstacles.

The primary purpose of a conduit junction box is to provide a secure and enclosed space for electrical connections, splices, and terminations. It allows for the consolidation and organization of wires, ensuring proper electrical continuity and preventing accidental contact or damage.

Some key features and functions of conduit junction boxes include:

Wire Termination: Junction boxes allow for the termination of electrical wires by providing connection points for switches, outlets, fixtures, and other electrical devices.

Wire Splicing: They facilitate the joining or splicing of wires together, allowing for the extension or branching of electrical circuits.

Wire Protection: Junction boxes protect electrical connections from external factors such as moisture, dust, and physical damage. This helps to prevent electrical hazards and ensures the longevity of the electrical system.

Code Compliance: In many electrical installations, the use of junction boxes is required by electrical codes and regulations to ensure safety and maintain proper installation standards.

Junction boxes come in various sizes and types to accommodate different wiring configurations and installation needs. They can be surface-mounted on walls, ceilings, or floors, or they can be recessed within the structure.

The specific design and features of a PVC LED box may vary depending on the intended application, such as indoor or outdoor use, the size and number of LED drivers or fixtures to be housed, and the requirements of the lighting installation.

The fan hook is typically made of metal and consists of a hook-shaped bracket that attaches to the ceiling joist or support structure. It has a threaded center hole or stud where the fan canopy or fan hanger bracket can be attached.

To install a ceiling fan using a fan hook, the hook is screwed or bolted into the ceiling joist or support structure. The electrical wiring from the ceiling is threaded through the center hole of the hook, allowing it to hang securely. The fan's canopy or hanger bracket is then attached to the threaded center hole or stud of the fan hook, providing a stable mounting point for the fan.

Mounting Spotlights: A spotlight box could provide a secure and stable mounting platform for spotlights. It may have pre-drilled holes or brackets to accommodate the installation of the spotlight fixture.

Wire Management: The spotlight box could include compartments or conduits to manage the electrical wiring required for the spotlights. This would help keep the wiring organized and hidden for a cleaner installation.

Protection and Safety: The spotlight box may offer protection for the electrical connections and wiring associated with the spotlights. It could shield the wiring from environmental factors such as moisture, dust, or accidental physical contact, reducing the risk of electrical hazards.

Aesthetic Integration: Depending on the design and materials used, a spotlight box could be intended to blend in with the surrounding architecture or décor, providing a seamless integration of spotlights into the space.

We are known for a best of its kind quality.

Our expert team gives you the right technical guidance to you.